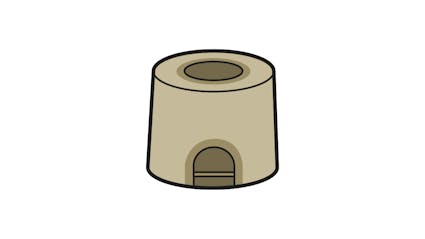

491 – Lime Kiln (Reconstruction)

The lime pit and the lime kiln in the Open-Air Museum were installed in the year 2000. The kiln was patterned after one that was partly extant near Zweilütschinen in the Bernese Oberland.

Solid and Elegant

Burnt and slaked lime met many needs: until the 20th century the walls of kitchens and stalls were painted with whitewash as a disinfectant. Lime mortar was a reliable binder for masonry walls. Burnt lime was stirred with sand and water to make the mortar. The mortar is permeable to air and yet durable; it hardens quickly and can last for hundreds of years. Not until the 20th century was lime mortar replaced by cement. Lime mortar also served for plastering walls: it clothed noble houses as well as churches and chapels and in some regions farmhouses in elegant white. These buildings stood out from dark wooden houses or from stone buildings with bare walls.

From Homemade to Industrial Product

Field kilns were usually simple: a stone drum about five metres (16 feet) in outside diameter enclosed a cavity as a round combustion chamber. Numerous place names like “Chalchofe” (lime kiln) testify to the construction of such field kilns in the alpine region until the early years of the 20th century. Larger kilns better suited to continuous operation had come into use as early as the 19th century. They were several metres high and sometimes twinned. Their operational principle was similar to that of industrial smelters for refining iron ore. They were also often used for burning tiles. They no longer served solely for home production. Like some mills, sawmills, tanneries or baking ovens, they stood on the threshold to industrial production. The kiln reconstructed at Ballenberg is similar to these proto-industrial kilns of the 19th century.

Production Method

Burning a charge of limestone takes about seven days and consumes more than 20 steres of wood: a bed of firewood is laid in the combustion chamber, which is then filled with limestone and the charge heated to a temperature of 1100 degrees Celsius. For a further three or four days, the fire is fed through the lower opening with wood until the top layer of limestone glows. After the kiln has cooled, the stones are removed, crushed and soaked with water in a pit. The resulting thick liquid is called “slaked lime”. According to the desired use (as plaster or mortar), sand or water is added to the lime. The product can be used immediately or stored in a pit for some time.

Ballenberg

Swiss Open-Air Museum

Museumsstrasse 100

CH-3858 Hofstetten bei Brienz

Opening hours Administration

3 November 2025 to 8 April 2026

From Monday to Friday

8.30 am to 11.30 am

1.30 pm to 4.30 pm

Opening hours

9 April to 1 November 2026

10 am to 5 pm daily