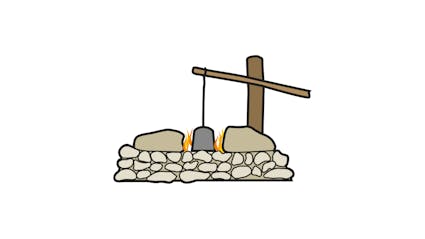

492 – Pitch melting oven (Reconstruction)

Resin used to be extracted by heating logs in the Pitch melting oven.

Extracting Resin

Coniferous trees, especially pines, contain a lot of resin in the form of pitch. It is extracted by boring a hole in the trunk of the tree and collecting the pitch that oozes out in a bucket. Alternatively, pieces of wood can be piled under a bell-shaped metal cover and heated by an external fire. The pitch then melts and flows out into a bowl sunk in the ground under the oven. From there a wooden pipe conducts it underground to a vessel where it cools and solidifies.

Major Trading Good

Extracting resin was a profitable business in the alpine regions: in 1588 there were more than 60 ”larch-borers” in the vicinity of Visp in the Valais. Especially northern Italians applied for licences to gather and export pitch. The raw material was freighted over the passes in barrels and on to the Mediterranean ports. The trade died out in the 19th century. Only a few ovens operated into the 20th century. The only surviving evidence of pitch-burning ovens are place names and the occasional oven in ruins in the forest.

What Use is Resin?

Resin served as fuel for light and fire. It was used in salves and bandages for healing wounds or infections of animals and humans. In addition, it was used for caulking barrels, shoes and ship’s hulls. It was used as an impregnant or as a sealant for porous objects. It could stretch out expensive candle wax or be used in soap or when scalding swine at slaughter. Chemicals and pharmaceuticals replaced the natural product resin in the 19th century: artificial soap, synthetic resins, salves with chemical additives and kerosene as fuel rendered the extraction of resin obsolete.

Ballenberg

Swiss Open-Air Museum

Museumsstrasse 100

CH-3858 Hofstetten bei Brienz

Opening hours Administration

3 November 2025 to 8 April 2026

From Monday to Friday

8.30 am to 11.30 am

1.30 pm to 4.30 pm

Opening hours

9 April to 1 November 2026

10 am to 5 pm daily