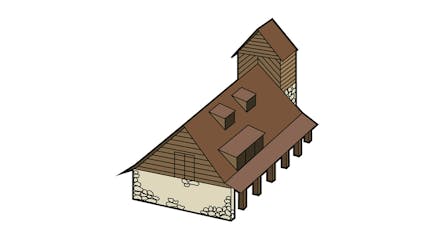

141 – Tilery from Péry, Berne, 1763

As a rule, master craftsmen built their own workshops. On the contrary, in Péry, the civil community initiated in 1763 the construction of a new tilery near the «Pré Gary» lime pit and a forest, which from now on supplied the most important materials.

1'000 degrees and 18'000 tiles

At Ballenberg traditional crafts are fostered and since 2018 tiles are being made once more. A craftsman shapes roof tiles, floor tiles and bricks. The historic shaft kiln can hold up to 18,000 pieces of items for firing. The blanks are first stored for several weeks in the large drying hall, then stacked tightly in the kiln and heated to 100 degrees to reduce the residual moisture. The firing process at around 1,000 degrees takes several days. In the past, five to seven assistants were busy lending each tiler a hand. The kiln was in operation five times a year.

Living and working under one roof

A small residential area was established for the tilemakers.The tilery as well as the chambers were covered with the first home-fired tiles in 1765. In addition to the lease the tile layer was obliged to deliver 300 litres of burnt lime to the citizens of Péry. The residential part wasn’t moved to Ballenberg, and the shaft kiln is no longer used for lime burning, as the Swiss Open-Air Museum already operates a separate lime kiln.

People like you and me

Nicolas Grandguenin, Jean Pierre Criblez, Jacob Zeller, Joseph Rohrbach and Edouard Bessire are the names of the Péry tile layers documented up until 1900. Today Ballenberg visitors come to work and support the tile maker in his work.

Making tiles

Clay,water,sand and fire – for thousands of years these ingredients have been used to make tiles to protect roofs. At Ballenberg this craft has come to life again. In the tilery from Péry, Berne (141), beaver tail roof tiles and floor tiles are made by hand. This requires a great deal of strength, skill and knowledge. Roots and stones have to be removed from the clay, the correct amount of sand has to be added, the lump of clay has to be skillfully knocked into the mould then the tile has to be painted and placed on a top shelf to dry.

Over 3,000 tiles, floor tiles and clay bricks can be dried at the same time in the tilery from Péry, Berne (141). All the finished and very fragile blanks are tested for their suitability, as the smallest mistake can cause them to shatter during firing.

The tilery from Péry relocates

The relocation of the tilery from Péry, Berne (141) in the years 2015 to 2017 has been documented on film.

Ballenberg

Swiss Open-Air Museum

Museumsstrasse 100

CH-3858 Hofstetten bei Brienz

Opening hours Administration

3 November 2025 to 8 April 2026

From Monday to Friday

8.30 am to 11.30 am

1.30 pm to 4.30 pm

Opening hours

9 April to 1 November 2026

10 am to 5 pm daily